WireTerminals

Automated wire processing:

WireTerminals

The wiring process in control panel construction is one of the most time-consuming steps in the entire manufacturing process – and this is exactly where our WireTerminals come in. Developed from our own requirements, we now offer sophisticated product series for fully automated wire assembly for control panel and machine construction.

The WireTerminal produces fully automated assembled wires for control panel wiring. Up to 36 different wires can be processed without the need for retooling. The wire diameter ranges from 0.5 mm² to 6 mm².

The wires are cut to length and labelled. Different end processings can be applied to both ends. The wires can then be deposited in a WireRail, fixated in tape chains, or simply discarded.

Fully automated wire processing

Our WireTerminal

Wire processing units

Wire ∅: 0.5 mm² to 6 mm²

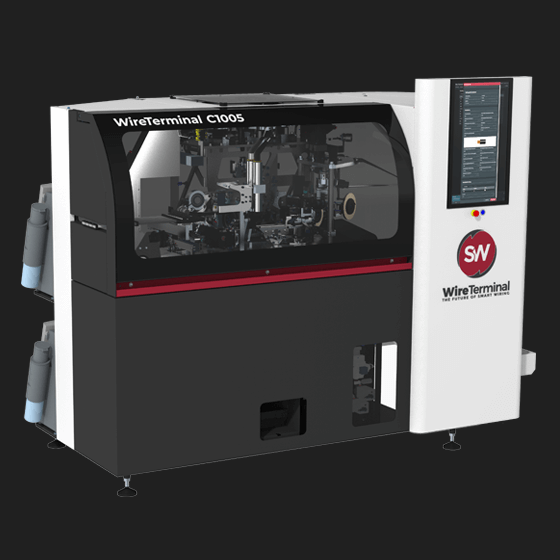

Fully automatic wire processing machine

with output via wire rail magazine or wire chain bundler

Wire ∅: 0.5 mm² to 6 mm²

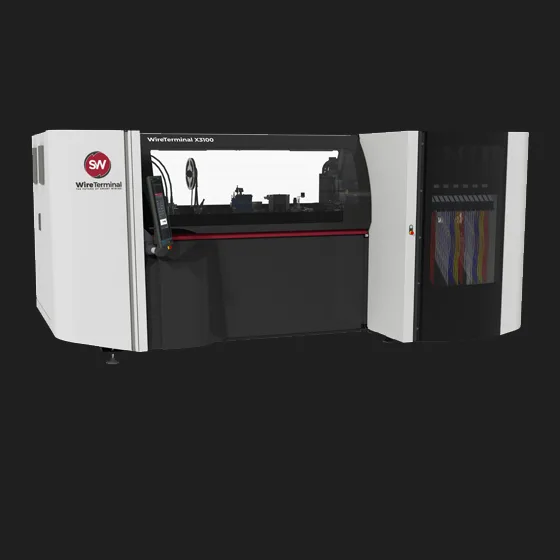

Fully automatic wire processing machine

with output via wire rail magazine and wire chain bundler

Wire ∅: 0.5 mm² to 6 mm²

Fully automatic wire processing machine

contact us for more information

Wire feed casette

Patented, simple and tool-free operation

During the production process, the WireTerminal can be used to load up to 36 wires with a cross-section of 0.5 mm² to 6 mm² simultaneously and process them without retooling. To process other wires, all that is required is to replace one of the up to three patented wire feed cassettes, each containing 12 wires, in one of the up to three positions.

The change can be carried out easily and without tools using a quick release. To do this, open the quick release and replace the current wire cassette with another one.

Each wire cassette is fitted with an RFID chip, which enables it to be clearly assigned. Reading the RFID chip makes the WireTerminal recognise which wires are equipped in the wire feed cassete and these wires are simultaneously released for production on the machine.

If the wire assignment on the wire cassette is changed, this change can simply be made on the touch display (24″). The wire assignments of the different wire cassettes are shown on the WireTerminal. All fine-core copper wires according to DIN VDE 0295, class 5 can be processed.

Labelling

Customised wire labelling

The labelling of the wires produced by the WireTerminal is applied with an inkjet printer. It is used to print an individual text on the wire in the colours black or white.

The WireTerminal is equipped with up to two printers, which can be used alternately without waiting time. This means that the wires for the control panel manufacturing are clearly labelled and easy to assign.

The position of the labelling on the wire can be selected individually or printed continuously.

Ferrules

Crimper

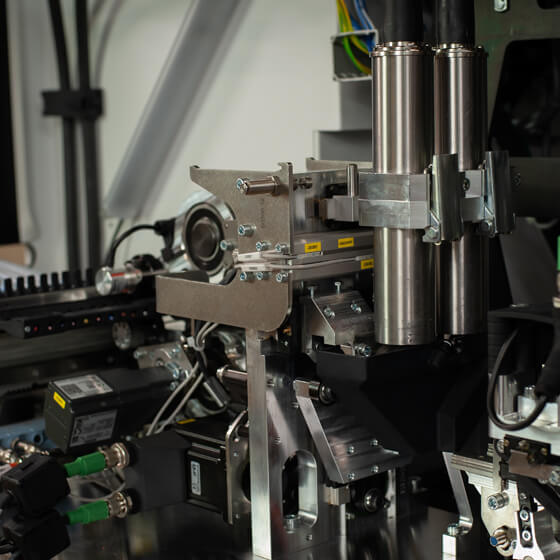

The five- or ten-fold crimpers developed in-house comprise five or ten vibrating conveyor bowls in which loose ferrules from 0.5 to 6 mm² can be prepared. The layout of the conveyor bowls can be customised to the individual requirements. Ferrules that comply with DIN 46228 are approved.

Ferrules with a length of 8 to 18 mm as well as ferrules with different lengths can be processed on the same wire. All ferrules with all cross-sections are crimped using a quattro crimping tool.

Wire ends

Wire end processing

With the WireTerminal, the following end processings are possible on both ends:

- Continuous partial stripping from 6 to 20 mm

- Continuous full stripping from 2 to 22 mm.

- Crimped-on ferrules with the dimensions

0,5 | 0,75 | 1 | 1,5 | 2,5 | 4 | 6. - Ferrule lengths from 8 to 18 mm.

- Ferrules according to DIN 46228.

It is also possible to crimp ferrules of different lengths to the respective ends of a wire.

Only with us

Output in patented WireRails

The wires produced by the WireTerminal can be stored in patented WireRails. The WireRail magazine can be individually equipped with up to 15 WireRails. Each cross-section between 0.5 and 6 mm² is stored in a separate WireRail.

The wires are sorted in a way that corresponds to the sequence used for control panel wiring. All wires with a ferrule crimped onto at least one end can be stored in the WireRail magazine. Due to the high capacity of the WireRails, the WireTerminal can produce wires over a long period of time without the need for manual intervention.

Once the order has been completed, the WireRails with the produced wires can be removed from the WireRail magazine and immediately made available at the workstation for the control panel wiring. The wires can then be removed individually from the WireRails in the predefined sequence and wired directly without having to remove any adhesive tape residue. Manual sorting of the wires is no longer necessary.

Wire output

Output in tape chains

The wires produced by the Wire terminal can also be fixed into wire chains using two adhesive tapes in accordance with the wiring sequence. Wires with different cross-sections from 0.5 mm² to 6 mm² can be arranged one behind the other.

Regardless of the end processing, all wires can be deposited this way. The finished tape chains are collected in a collection tray.

Once the job has been completed, they can be removed and made available for control panel wiring at the workstation.

Simple operation

Operation and interfaces

The production-optimised operation of the WireTerminals are controlled via a 24" touch display. The order data for the wire sets can be transferred to the terminal in many file formats. Possible examples include eport files from ECAD systems as well as XLSX, CSV, or TXT files. Our in-house developed software is tailored to various requirements and preparations, as well as all kinds of possible input errors that could occur.

In addition, the production status of the WireTerminal can be monitored and controlled at any time from different workstations (e.g. work preparation, workshop management) via a network connection.

Reduce production costs.

Save time and material.

Drastically reduce errors. Consistent wire quality

Amortisation

from 100 orders / year

Say goodbye to skills shortages. Secure productivity.

Frequently asked questions:

What is meant by "automatic wire assembly"?

In automated wire processing, wires are cut to length, labelled, processed and - if required - fitted with ferrules at the ends (crimping) fully automatically. Our WireTerminal machines enable this process without manual retooling - ideal for series production in switch cabinet construction or mechanical engineering.

Even smaller projects customised to customer requirements and small series can be produced with the WireTerminal can be manufactured easily and, above all, economically.

What is the difference between cable processing and wire processing?

The terms are often used interchangeably. Technically speaking Cable processing the processing of multi-core or shielded cables, while the Wire processing usually refers to single-core wires. Our WireTerminals specialise in the processing of single-core wires - including crimping, labelling and bundling as tape chains.

Is the WireTerminal a cable processing machine?

The Wireterminal performs the same tasks as a cable processing machine, but is technically referred to as an automatic wire processing machine. The difference lies in the terminology: In Austria, single-core cables are referred to as "wire" and multi-core cables as "cable". For users, this means that the Wireterminal, wires can be cut to length, stripped, labelled and crimped fully automatically - precisely the processes that are required in cable and wire assembly.

Is the WireTerminal a crimping machine?

The Wireterminal offers far more functions than a classic automatic crimping machine. While an automatic crimping machine or crimping machine was primarily developed for stripping wires and crimping contacts (crimping), the Wireterminal also performs many other wire assembly steps: automatic cutting to length, stripping, crimping, labelling and the provision of complete wire sets as chain bundles. It therefore combines the tasks of an automatic stripping and crimping machine with extended functions for fully automatic wire assembly - ideal for efficient control cabinet construction.

How does the WireTerminal improve the quality of my wire processing?

The Wireterminal ensures documented, consistently high quality. Wire end ferrules from 0.5 to 6 mm² are securely crimped using an in-house developed crimper - different lengths are also possible. The clear wire labelling makes control panel manufacturing easier and reduces errors. This significantly minimises rejects.

What is special about the WireRail magazine of the WireTerminal?

The Patented WireRail magazine provides for Organised, production-ready storage of the pre-assembled wires - ready for immediate use in assembly. Unlike the classic wire collection tray, the wire ends do not get tangled and no adhesive tape residue needs to be removed.

This saves time, creates an overview and even enables wiring by assistants.

What does a crimper do in a fully automatic wire processing machine?

A Crimper is a component in the fully automatic machine that presses the wire end ferrules onto the wire or cable ends. The terminal in the WireTerminal C3010 integrated 10-way crimper can crimp wire end ferrules from 0.5 to 6 mm² automatically - even with different lengths on both sides of the wire. This saves time and increases process reliability.

What are the benefits of a higher degree of automation in cable processing?

A higher degree of automation Reduces production costs, Reduces set-up and throughput times and makes your company more competitive. With the Wireterminal can be used for up to 36 different wire types processed in one pass become - without retrofitting. The combination of efficiency, speed and consistent quality pays off in every production process.

How does the WireTerminal help with the shortage of skilled labour in enclosure construction?

The WireTerminal automates the entire wire processing job: cutting to length, printing, crimping and depositing are fully automated - without any manual intervention. This means that skilled workers can be deployed specifically in assembly, while semi-skilled workers can wire quickly and safely thanks to clearly labelled wires. The training time for new employees is significantly reduced.

Are there comparable providers or alternatives to WireTerminal?

Yes, there are several established suppliers in the field of automated wire and cable assembly - including our long-standing sales partner Rittal, Komax/Schleuniger or Metzner Mechanical Engineering. Each of these manufacturers has its own strengths and specialisations.

We at SW Automation develop with the WireTerminal C3010 an innovative, modular solution as an alternative to existing systems - with a focus on Practical relevance, Process optimisation and Flexibility. Examples of this are our Patented rail magazinewhich can be used to transport finished wires directly to the workplace in an organised manner, and our in-house developed crimperwhich removes loose wire end ferrules from 0.5 - 6 mm² efficiently - without manual set-up.

Our goal: a smart solution that fits perfectly into your production process.

You are here: Home page " Solutions