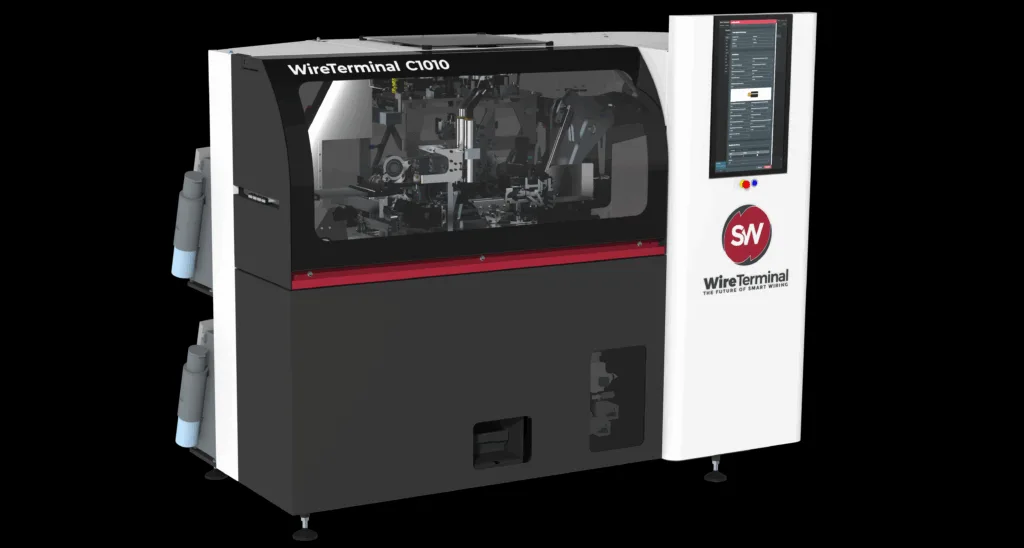

The WireTerminal C1010 produces assembled wires for control panel manufacturing fully automatically. Up to

12 different wires can be processed without retooling. The wire cross-section ranges from 0.5 mm² to 6 mm².

The wires are cut to length, labelled and different end processings can be applied to both ends. The individual wires are then output either in patented WireRails or tape chains.

The WireRail magazine can be individually equipped with up to five WireRails. Each cross-section between 0.5 mm² and 2.5 mm² is stored in a separate rail. The wires are sorted so that they correspond to the sequence of control panel wiring. All wires with a ferrule crimped onto at least one end can be stored in the WireRails. Due to the high capacity of the WireRails, the WireTerminal can process wires over a longer period of time without the need for manual intervention. Once the job is complete, the WireRails with the produced wires can be removed from the WireRail magazine and immediately made available at the workplace for control panel wiring. The wires can then be removed individually from the WireRail in the predefined order and wired directly without having to remove adhesive tape residue.

When dispensing tape chains, wires are fixated in place using adhesive tape according to the wiring sequence. Wires with different cross-sections from 0.5 mm² to 6 mm² can be arranged one behind the other. Regardless of the end processing, all wires can be stored here. The finished tape chains are collected in a collection tray. They can then be removed from the tray during or after completion of the order and made available for control panel manufacturing at the workplace.

Standard equipment

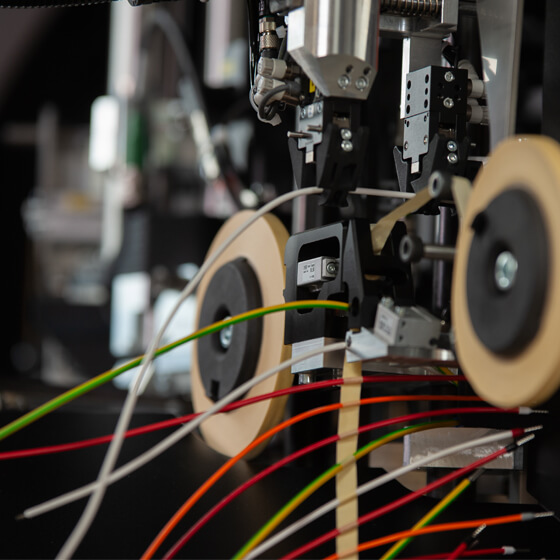

Wire feed casette

During the production process, the WireTerminal can process

12 wires with a cross-section of 0.5 mm2 up to 6 mm² without retooling. To process other wires, only the wire feed cassette needs to be replaced.

The change can be carried out easily and without tools using a quick release. This is opened and the current wire cassette is replaced with another one. Each wire feed cassette is fitted with an RFID chip so that it can be clearly assigned.

Reading the RFID chip makes the WireTerminal recognise which wires are set up in the wire feed cassette and the wires are simultaneously released for production on the machine. If the wire assignment on the wire cassette is changed, this can simply be updated on the display. The wire assignments of the different wire cassettes are shown on the WireTerminal. All fine copper wires according to DIN VDE 0295 class 5 can be processed.

Wire labelling

The labelling of the wires produced by the WireTerminal is applied with an inkjet printer. This is used to print an individual text on the wire in the colours black or white.

The WireTerminal is equipped with up to two printers, which can be used alternately without waiting time. This means that the wires for the control panel manufacturing are clearly labelled and easy to assign.

The positioning of the labelling on the wire can be selected individually or printed continuously.

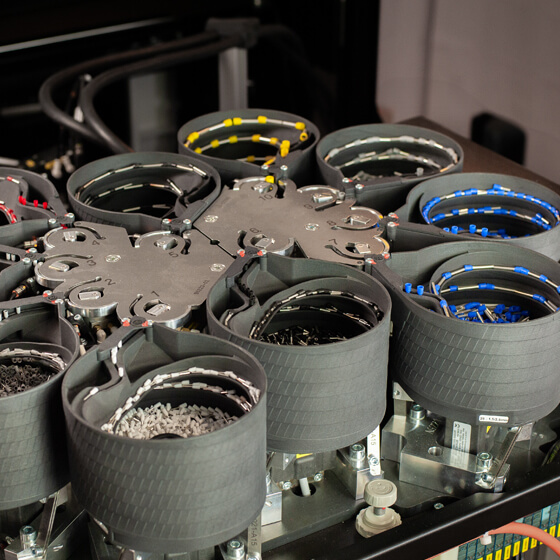

Crimper

The ten-way crimper developed in-house comprises ten vibrating conveyor bowls in which loose ferrules from 0.5 mm² to 6 mm² can be equipped.

All ferrules that comply with DIN 46228 are approved. Ferrules with a length of 8 to 18 mm can be processed, as well as different ferrule lengths on the same wire.

All ferrules with all cross-sections are crimped using a quattro crimping tool.

Output in WireRails

When dispensing in WireRails, the wires are deposited individually. The WireRail magazine can be individually equipped with up to 5 WireRails for this purpose.

Any cross-section between 0.5 mm² and 6 mm2 is stored in a separate WireRail. The wires are sorted in such a way that they correspond to the sequence used for the control panel wiring. All wires can be deposited in WireRails that have a ferrule crimped onto at least one end.

Due to the high capacity of the WireRails, it is possible for the WireTerminal to produce wires over a long period of time without the need for manual intervention. The WireRails with the produced wires can be removed from the WireRail magazine once the job has been completed and provided at the workstation for the control panel wiring immediately.

The wires can be removed individually from the WireRails according to the predefined sequence and wired directly without having to remove any adhesive tape residue.

or

Output in tape chains

When outputting in tape chains, wires are fixated using adhesive tape according to the wiring sequence.

Wires with different cross-sections from 0.5 mm² to 6 mm2 can be arranged one behind the other. All wires can be placed here regardless of the end processing.

The finished wire chains are collected in a collection tray. They can then be removed during or after completion of the job and made available for control panel wiring at the workplace.

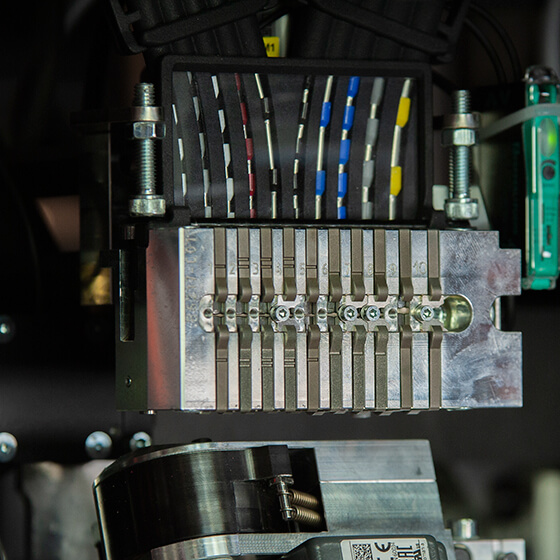

Wire end processing

With the WireTerminal, the following end processings are possible on both ends:

> Continuous partial stripping from 6 to 20 mm

> Continuous full stripping from 2 to 22 mm

> Crimped-on ferrules 0.5 | 0.75 | 1 | 1.5 | 2.5 | 4 | 6

> Length of ferrules from 8 to 18 mm

> Ferrules in accordance with DIN 46228

It is also possible to crimp ferrules of different lengths on the same wire at each end.

Operation and interfaces

A 24" touch display is used for the production-optimised operation of the WireTerminals.

The order data for the wire sets can be loaded onto the WireTerminal in many file formats. Possible examples include export files from ECAD software as well as XLSX, CSV, or TXT files.

In addition, the production status of the WireTerminal can be monitored and controlled at any time from different workstations

(e.g. work preparation, workshop management) via a network connection.